"Due to the USMCA requiring the certificate of origin for supplies to be national, the company already has 70% of its raw materials locally sourced; however, we are still looking for more suppliers," commented Eduardo David Salas, Plant Manager of CT Automotive Systems de México.

The executive mentioned that the company currently also sources materials from China but intends to replace them with Mexican suppliers who meet the specifications.

"What we bring from abroad are specific parts like decorative frames, which are painted by sister plants in China, but the rest we seek to be national," he said.

To be part of the value chain, suppliers can have ISO 9001: 2015 certification and IATF 16949. "After we get to know the suppliers and their operational capabilities, we develop them with audits and evaluations. We then send the information to the clients and relevant areas to ensure the supplier meets the requirements," Salas explained.

The executive indicated that the ideal supplier is one whose location allows them to save on logistics costs and has experience in the automotive industry, quality certifications, and offers competitive prices.

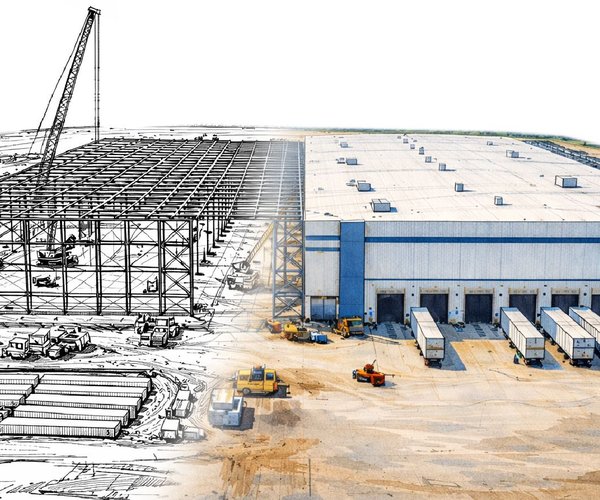

Automotive Operation

CT Automotive Systems México has plants in China and Turkey. The company arrived in Mexico in 2022, specifically in Puebla, intending to serve the American market. From this industrial plant, the company assembles kinematic parts, covered pieces, air conditioning diffusers, and parts like armrests and console covers, among other products.

At its Puebla plant, the company has various operational areas, including plastic injection, PVC cutting, vinyl, sewing, and covering areas.

The company serves automakers such as Ford and GM, as well as Tier 1 suppliers like Marelli. The executive estimated that of all its production in Mexico, 80% is exported, mainly to the United States, while the remaining 20% stays in Mexico (primarily to Marelli, which sells to Nissan and Mazda).