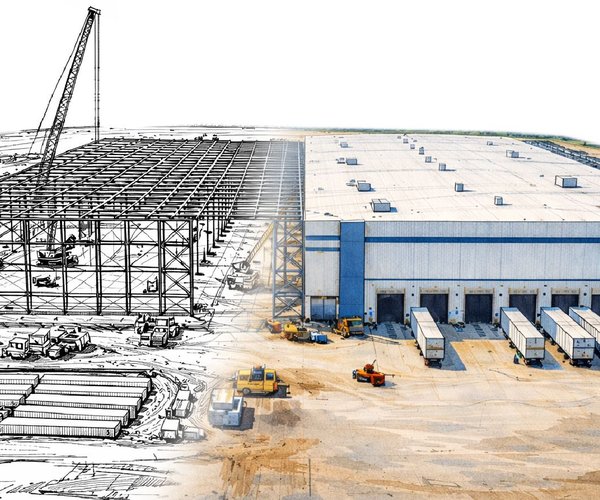

Rangel mentioned that because the company is about to open an additional plant in Puerto Interior Guanajuato, they will be looking for suppliers of all types. "It's good to start developing local suppliers and reduce imports, especially now that we are growing," said Rangel.

Requirements to Become a Supplier

To be part of the company's value chain, suppliers must have the same certifications as Plasma Automation, such as AS 9100 and ISO 9001:2015.

"If they don't have these certifications, we ask that they be capable of supplying us, that they have quality processes, but for that, we conduct a thorough evaluation where costs, quality, and especially traceability are essential," Rangel added. "The parts are critical; if they fail, they can cause serious incidents, especially in the aerospace sector," he emphasized.

A Specialized and Integrated Company

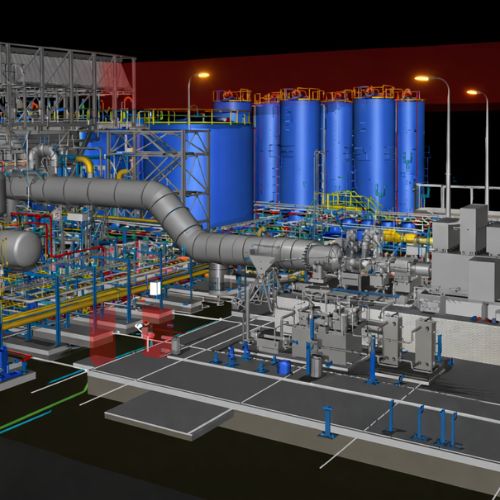

GPA focuses on offering comprehensive services and products, providing customers with solutions through engineering development, manufacturing, and logistics, with over 30 years of experience in the metalworking field.

The company is estimated to have 16 business units serving various industrial sectors, including medical, molds, dies and tooling, rail, automotive, and even aerospace.

From its plant in Guanajuato, GPA manufactures water and laser plasma cutting systems. It is worth noting that the company also has an Innovation and Mentefacture Park, providing significant advantages for both the industry and the development of innovative projects.