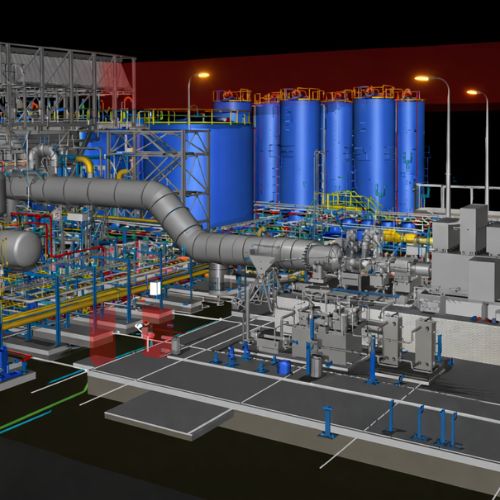

Production at these industrial sites includes fuel tanks, compressed air tanks, and aluminum air storage tanks for heavy and medium-duty trucks, as well as internal combustion SUVs.

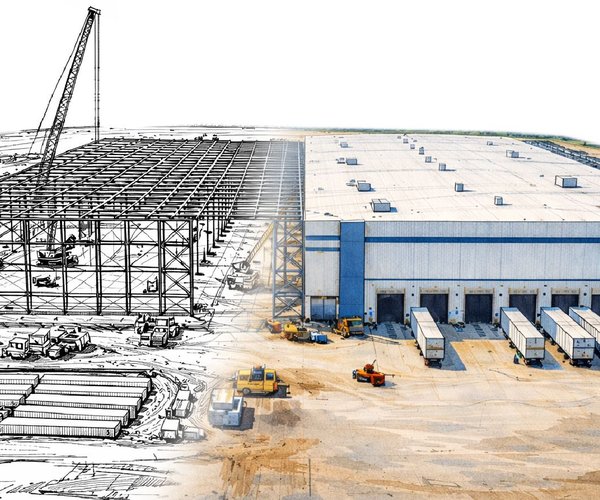

Although the exact location of this third facility has not been disclosed, it is known that it will manufacture custom-made aluminum components through die-casting and re-casting processes. The plant is expected to be operational by next year.

Héctor Núñez, General Director of SAG Mexico, highlighted recent sales of approximately 80 million euros, as well as additional orders valued at over 30 million euros, which has driven the decision to establish this new facility to meet growing demand.

“With our strategic location close to major OEMs and our extensive know-how in the development of custom products that facilitate vehicle construction, we have already attracted many satisfied customers who appreciate the quality of our products and our flexibility in logistics,” Núñez stated.

The company has a presence in six countries: Mexico, the United States, Austria, Slovakia, Spain, and the

Netherlands.

In 2009, SAG inaugurated the Santa Catarina plant in Nuevo León and began Tier I production for BMW. In 2015, it commenced Tier I production for brake air accumulators for FTL (DTMA). Three years later, it began Tier I production for FCA and a year after for Ford as a Tier II supplier. In 2020, it relocated its production to the State of Mexico and initiated Tier II production for General Motors.

Presence in North America

SAG Mexico is a subsidiary of SAG Motion and an international supplier of aluminum and steel components for the automotive and commercial vehicle industries. The company serves customers in Mexico and the United States.

The product range includes fuel and oil tanks, air tanks, and special products. Among its clients are major commercial vehicle OEMs and leading electric vehicle OEMs in North America.