The range includes straight linear guide rails (21355), renowned for their simplicity and reliability in linear motion.

They are available in standard lengths of 500, 1000, and 2000 mm, offering versatile options for top mounting and compatibility with roller guide carriages to ensure smooth movement and high load capacity. These are ideal for transportation applications, such as interior doors, providing quiet and reliable operation while enhancing efficiency and comfort. On the other hand, the curved linear guide rails (21356) are designed for situations where straight-line movement is not feasible.

Flexibility

These guides offer great flexibility for navigating predefined curves and optimizing space in environments with limitations.

The components accommodate complex motion profiles essential for precision applications such as CNC machining and 3D printing, ensuring accuracy and repeatability along curved paths. Norelem’s roller guide carriages complement the linear guide rails.

The roller guide carriage for straight linear guide rails (21350) compensates for deviations of approximately 0.05 mm, making it ideal for maintaining health and safety standards.

Meanwhile, the roller guide carriage for linear guide rails (21351) expands versatility with a tolerance range of about 0.5 mm, making it perfect for the packaging industry, as it is suitable for both straight and curved paths on rails, allowing efficient and precise transport of products.

These carriages excel in performance, with a maximum acceleration of 50 m/s² and a travel speed of up to 5 m/s. With a unilateral preload mechanism, these components adapt to the rail contour, ensuring constant resistance to slippage, reducing wear over time, and simplifying installation.

These components also eliminate the need to adjust the rollers to the rail width using an eccentric pin, ensuring smooth, slip-free movement while streamlining the process.

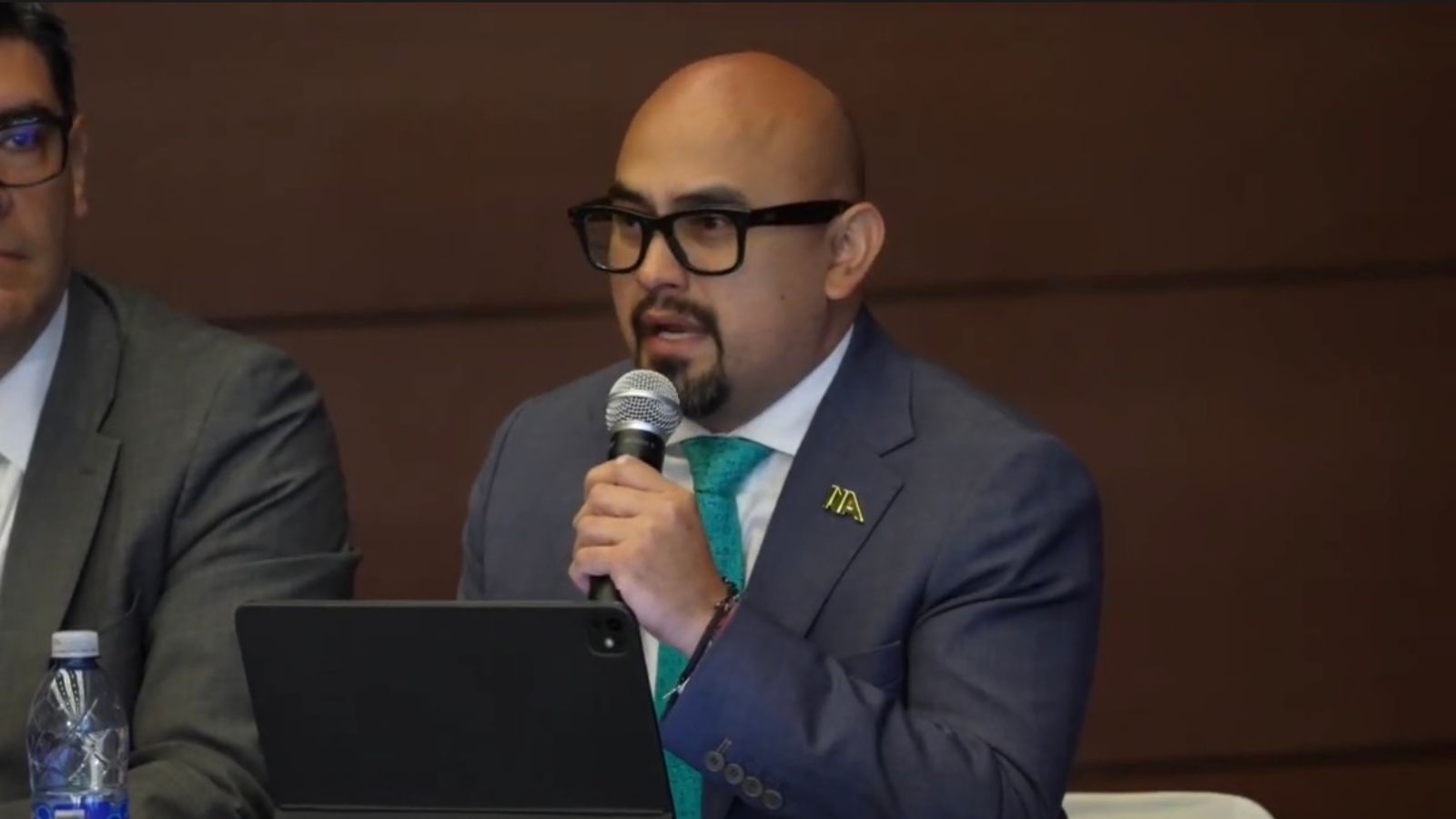

Martín Palacios, Managing Director of norelem Mexico, commented: "Our expanded range of linear roller guides is designed to meet the rigorous demands of modern industrial applications. Whether in packaging, food processing, or transportation, these guides offer unparalleled precision, reliability, and ease of use, demonstrating our commitment to providing solutions that enhance operational efficiency and longevity."

Norelem's linear roller guides stand out for their unwavering commitment to smooth motion and optimal performance, serving a variety of industries and ensuring that businesses can rely on the consistent excellence of their linear motion solutions.

To discover norelem's new range of linear roller guides and find the perfect solution for your application, visit norelem’s website.

Specialized Company

With over 65 years of manufacturing and supplying parts and components to the mechanical engineering industry, and committed to expanding its wide range of products, norelem provides more than 100,000 high-quality standard components for machinery and automation.

From new products every month to fast and reliable guaranteed delivery times, norelem understands the fast-paced nature of the engineering industry. Additionally, with 12 locations worldwide, norelem's team is available to provide on-site technical assistance to its customers, wherever they are.

Norelem's online store is available to customers, allowing them to conveniently order standard parts at any time. There, customers can also access norelem's extensive CAD data to ensure efficient designs and save considerable time when specifying products.