To carry out a manufacturing enterprise is risky and exhausting, not only because of the lack of inputs, but also because of the lack of knowledge that exists, for example, less than 1% of these SMEs have an international certification.

This is highly critical, because with the rise of the nearshoring phenomenon, it means that their participation will be limited. Obtaining an ISO can cost up to 200,000 pesos, but its price increases during the audit, purchase of new equipment, digitalization, among a long etcetera. Adding to this is the difficulty of accessing credit. The Bank of Mexico points out that high interest rates, numerous requirements and inflexible terms are the main reasons that limit SMEs.

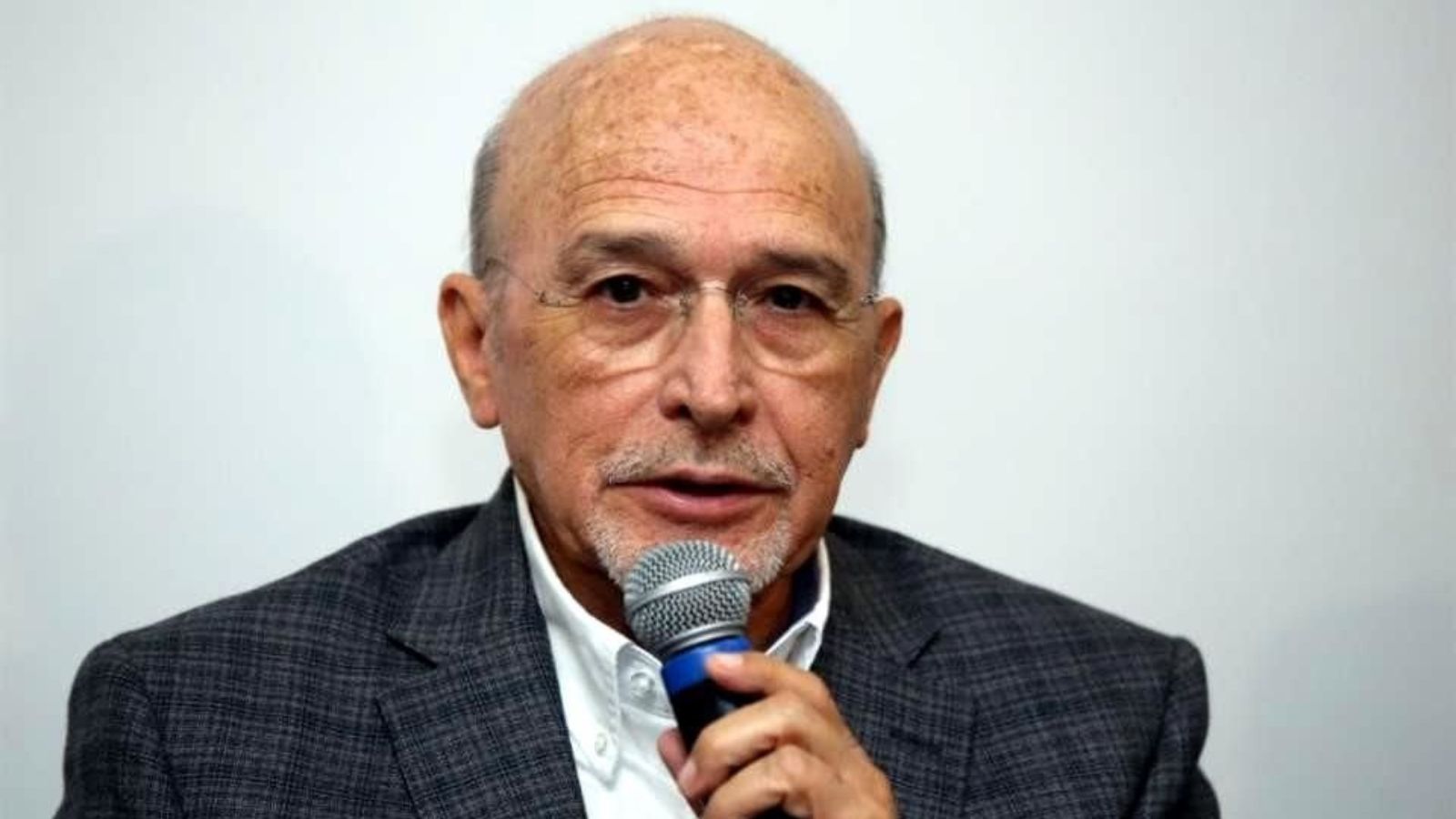

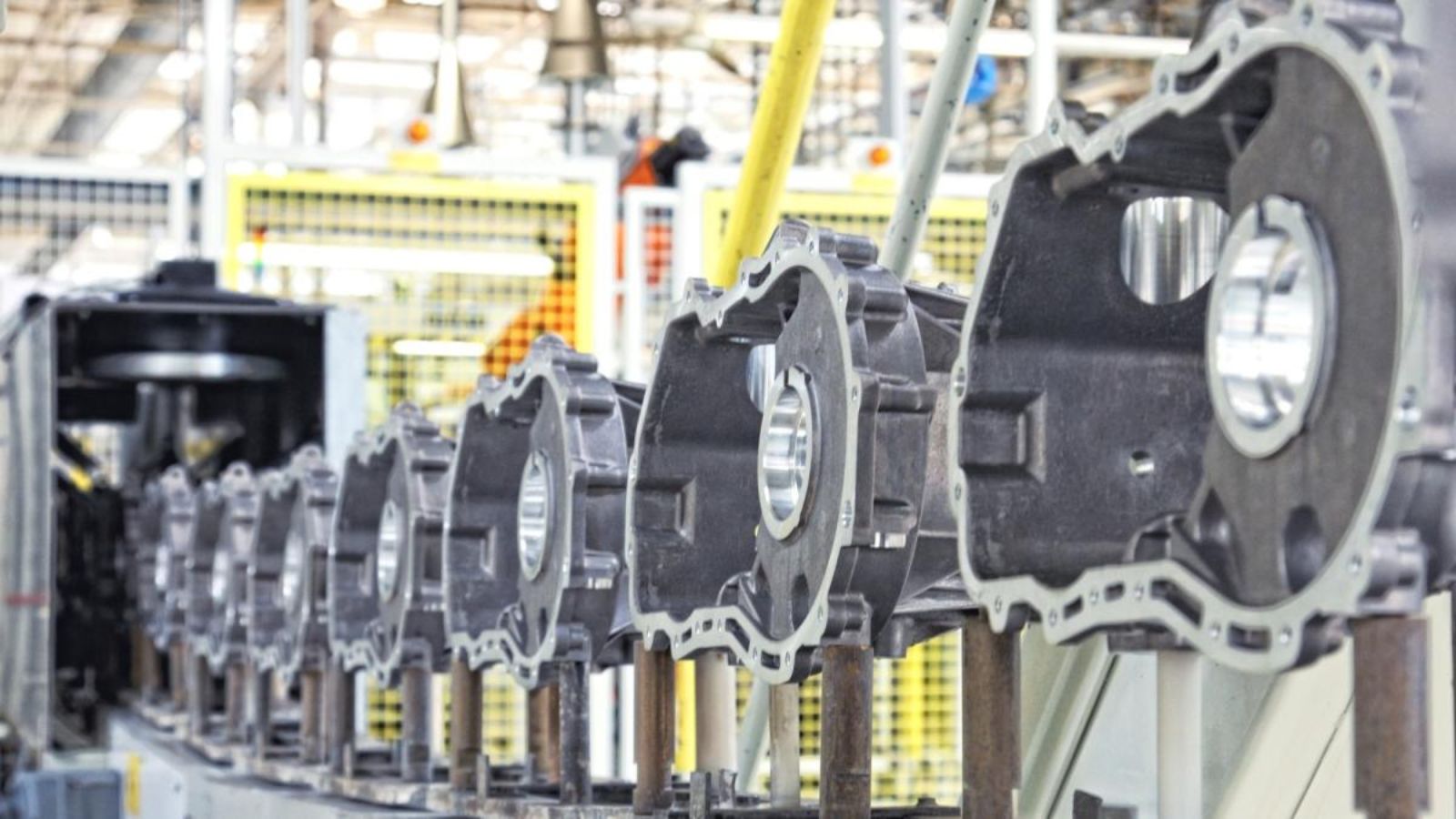

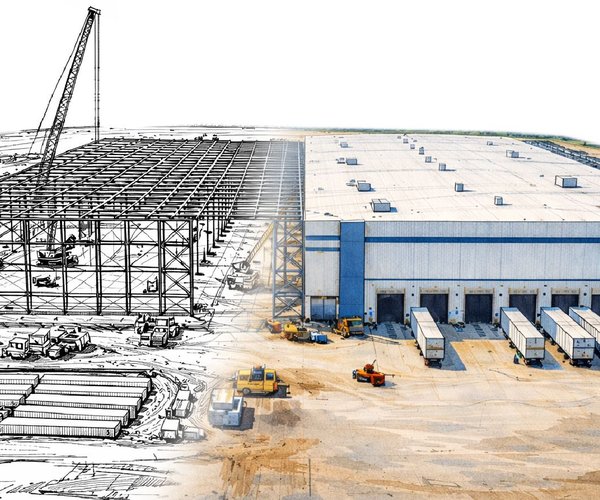

These types of problems are not new. More than forty years ago, when Hultek's foundations were laid, technology was scarce, machinery was not readily available and handmade processes were the norm.

Development was a trial-and-error gamble and a major financial risk.

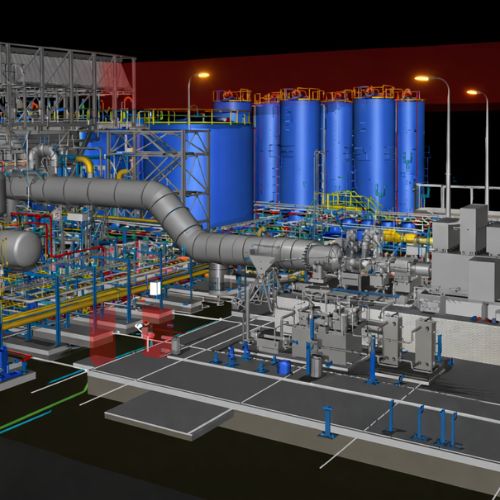

Today, even for the big fish, to talk about robotization or automation is to touch sensitive fibers, so demanding this from SMEs is too much, considering how uneven the game is.

But now is a good time to generate development programs and strategies to ensure their livelihood. We leaders must mark the way and help them join groups that offer an extra boost.

At the end of the day, just like them, we also started out the same way: with the dream of entrepreneurship.