For the company, reducing delivery times to increase efficiency is paramount, as logistical costs and delays in material deliveries are issues that need to be addressed. This requires suppliers who can meet their deadlines and agreements.

“For us, it is also very important that suppliers are reliable and fulfill their promises, both in terms of quality and in response times for quotations and delivery dates. Post-sales support is also of great importance, meaning they should be attentive to their clients' needs,” Hernández commented.

Currently, it is estimated that 80% of the company's indirect inputs are sourced nationally, with only 20% being foreign. However, they continue to seek more Mexico-based suppliers to further enhance their logistical and delivery efficiency. The company is currently looking for suppliers of spare parts, machining services, and other related services.

Automotive Operations

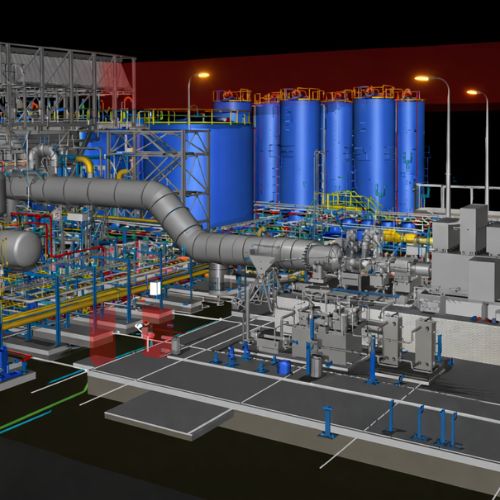

Woco Tech operates two industrial plants in the country, one located in the Bernardo Quintana Industrial Park in Querétaro, and another in Lagos de Moreno, Jalisco. The first industrial plant specializes in the injection molding of plastic automotive parts, such as pedals, filters, actuators, and hoses, while the other industrial plant focuses on rubber injection molding.